We are a dynamic and enthusiastic engineering consulting, development, supply, and service firm. We take pride in our engineering expertise and have created effective and practical solutions for clients across various industries.

We provide solutions tailored to meet the evolving needs of our clients, ensuring that they comply with regulations or address specific customer requirements. If you are interested in any of the products we offer or if you could benefit from our innovative services, simply reach out, and we will create a customized solution for you.

WELCOME TO FAST MOTORS FABRICATION SERVICES

OUR PRODUCTS

HYDRAULIC TAIL LIFT

FIRE FIGHTING VEHICLE

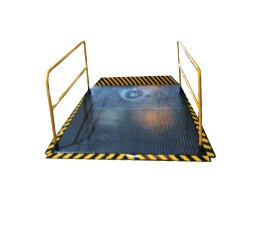

HYDRAULIC LOADING DOCKS

GRAB TRUCK

BIKE TIPPER

MEDICAL WASTE COLLECTION TRUCK

MIXER TRAILER

WATER TRUCK

OGRA COMPLIANT TANKERS

MECHANICAL SWEEPER

POLICE VAN

MULTI LOADER

ROAD WASHER

GARBAGE COMPACTOR

MINI TIPPER

DUMP TRUCK

Truck body fabrication refers to the process of building and assembling the structure or body of a truck. This typically involves designing, cutting, bending, welding, and finishing metal parts to create a robust and functional truck body.

Here are the main steps in truck body fabrication:

Design: The process starts with designing the truck body, where the specifications and requirements are outlined. This includes considering the truck’s purpose, payload capacity, size, and any specific features or compartments needed.

Material selection: Choosing the right materials is essential for durability and performance. Steel, aluminum, and composites are commonly used in truck body fabrication. The choice of material depends on strength, weight, corrosion resistance, and cost.

Cutting and shaping: Once the design and materials are finalized, the metal components are cut and shaped according to the specifications. Tools like saws, shears, or laser cutters are often used for this step.

Bending and forming: After cutting, the metal components are bent or formed into the desired shape using equipment such as hydraulic press brakes or rollers.

Welding and assembly: The components are then welded together to form the truck body. Welding methods like arc welding or MIG/TIG welding are commonly applied to ensure strong, secure joints.

Reinforcement and strengthening: Depending on the truck’s intended use and load capacity, additional reinforcements like braces, gussets, or support beams may be added to increase the structure’s strength and durability.

Finishing touches: Once the main body structure is complete, finishing tasks are carried out, such as grinding welds, sanding, smoothing edges, and applying protective coatings or paint to prevent corrosion.

Installation of components: After the truck body is fabricated, additional components like doors, windows, hinges, locks, lights, and handles are installed. These may be pre-fabricated or customized to meet specific requirements.

Truck body fabrication requires skill and knowledge in engineering, metalworking, and fabrication techniques. Professionals ensure the truck body meets safety standards, functional needs, and aesthetic considerations.